A Guide to Corrosion-Resistant Metals

Understanding Corrosion and Its Resistance

Corrosion is the chemical degradation of metals in their environments, reverting them to more chemically stable forms like oxides, hydroxides, or sulfides. The most familiar form is iron rusting, transforming into iron oxide in the presence of oxygen and water. Corrosion resistance is the metal's ability to withstand environmental degradation, achieved either through its inherent chemical composition or by applying protective coatings and treatments.

Key Mechanisms for Corrosion Resistance

- Oxidation Layers: Metals like aluminum naturally form protective oxide layers that prevent further oxidation.

- Coatings: These include paints and metallic platings that shield the metal from corrosive agents.

- Alloying Elements: Adding elements like chromium, nickel, and molybdenum to metals increases their resistance by promoting the formation of protective layers or altering electrochemical behaviors.

Popular Corrosion-Resistant Metals and Their Uses

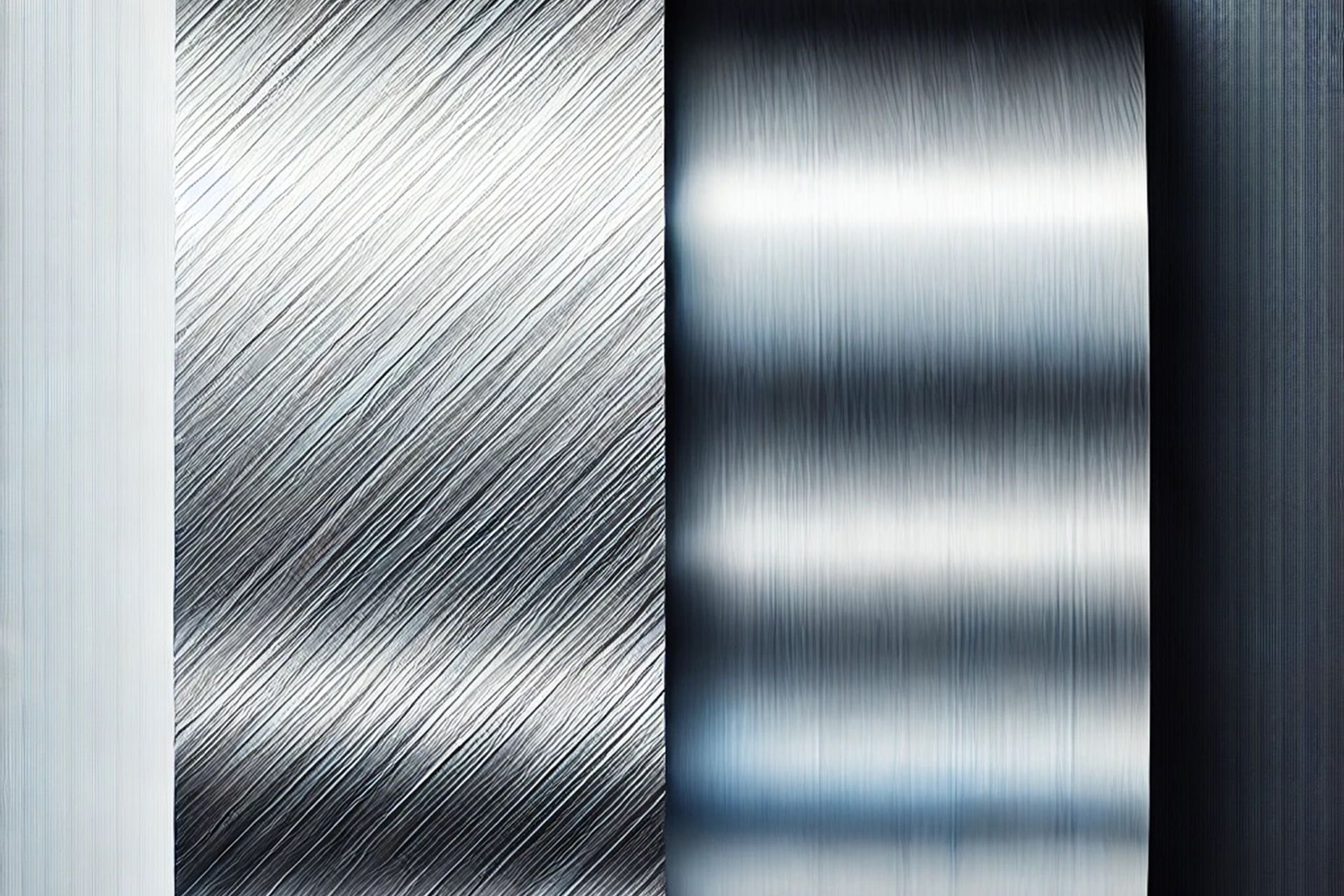

Stainless Steel

Comprising iron, chromium, and often nickel and molybdenum, stainless steel's corrosion resistance chiefly comes from chromium, which forms a self-healing oxide layer. The most common grades are:

- 304 Stainless Steel: Balanced properties suitable for multiple environments.

- 316 Stainless Steel: Contains molybdenum, boosting resistance to chloride, ideal for marine uses.

Applications: Widely used in medical equipment, kitchen appliances, and marine structures.

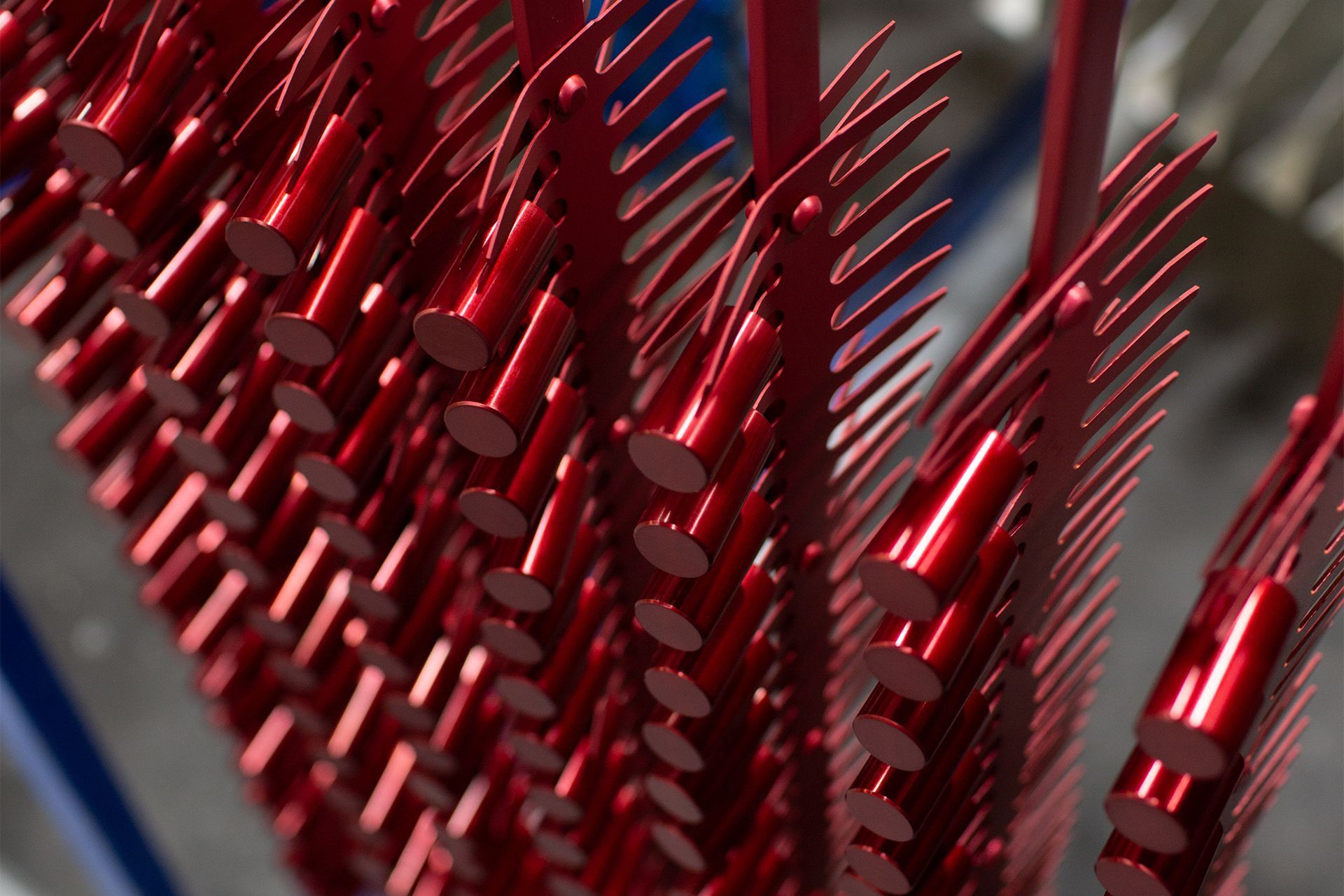

Aluminum

Known for its lightweight yet strong properties, aluminum forms a natural oxide layer for protection, further refined by processes like anodizing.

Applications: Extensively used in aerospace, automotive, and construction due to its strength and weight advantages.

Titanium

Exceptionally resistant to corrosion in environments like seawater and chlorine solutions, titanium is prized for its strength-to-weight ratio and biocompatibility.

Applications: Crucial in medical implants, aerospace parts, and chemical processing equipment.

Copper and Copper Alloys

Copper inherently resists corrosion in marine and electrical contexts and develops a protective patina over time. It also boasts antimicrobial properties, making it suitable for sanitary applications.

Applications: Plumbing, electrical components, and decorative arts. Alloys like brass and bronze are used in marine fittings and musical instruments.

Specialized Alloys (Nickel, Inconel, Hastelloy)

For extreme conditions, specialized corrosion-resistant alloys based on nickel, chromium, and other elements are developed to offer superior resistance.

Applications: Used in chemical processing, offshore drilling, and power generation.

Applications Across Industries

→ Marine: Stainless steel, aluminum, and copper alloys are vital in marine settings for their resistance to saltwater.

→ Aerospace: Lightweight, strong, and corrosion-resistant materials like aluminum and titanium are essential for aircraft and spacecraft components.

→ Automotive: Corrosion-resistant materials ensure the longevity and safety of automotive parts exposed to various chemicals and environments.

→ Medical: Materials must be biocompatible as well as corrosion-resistant, with stainless steel and titanium being predominant in implants and surgical tools.

Choosing the Right Corrosion-Resistant Metal

Selecting the appropriate metal or alloy is crucial, depending on environmental conditions, mechanical needs, and economic considerations. Innovations in materials continually alter the performance and lifespan of these metals, reducing maintenance costs and improving efficiency across industries.

Investing in advanced corrosion protection strategies like specialized coatings, corrosion inhibitors, and cathodic protection systems can further extend the durability and functionality of metallic components in harsh environments. By integrating these advanced materials and techniques, industries can significantly bolster their operational longevity and efficiency, securing their future against the inevitable challenge of corrosion.