How to Keep Guns from Rusting with Metal Finishing

Metal finishing plays an important role in increasing your firearms' durability, performance, and aesthetic appeal. For business owners and manufacturers in the firearm industry, choosing the right metal finishing method is crucial to keeping firearm parts rust-free and functional, even in challenging environments. Proper finishing not only protects against corrosion but also improves the overall look and feel of the firearm.

What is Metal Finishing?

Metal finishing refers to applying a protective layer to the surface of metal components to increase their durability, resistance to corrosion, and overall performance. For firearms, metal finishing is particularly needful as it protects against environmental factors like humidity and moisture, leading to rust and other forms of corrosion. In addition to its functional benefits, metal finishing offers aesthetic improvements, giving firearm components a professional, polished look.

How Metal Finishing Keeps Guns from Rusting

The primary function of metal finishing for guns is to provide enhanced protection against rust and corrosion caused by exposure to elements such as humidity, sweat, and rain. Corrosion-resistant firearm coatings ensure that the metal components are shielded from moisture, preventing rust from forming. This is especially important for gun shop owners and manufacturers who need to maintain the quality of their products and ensure customer satisfaction.

While anodizing does boost its aesthetic appeal, rust prevention for firearms primarily prevents damage to critical components. By choosing the best metal finishing method, professionals in the firearm industry can provide long-lasting protection for their products.

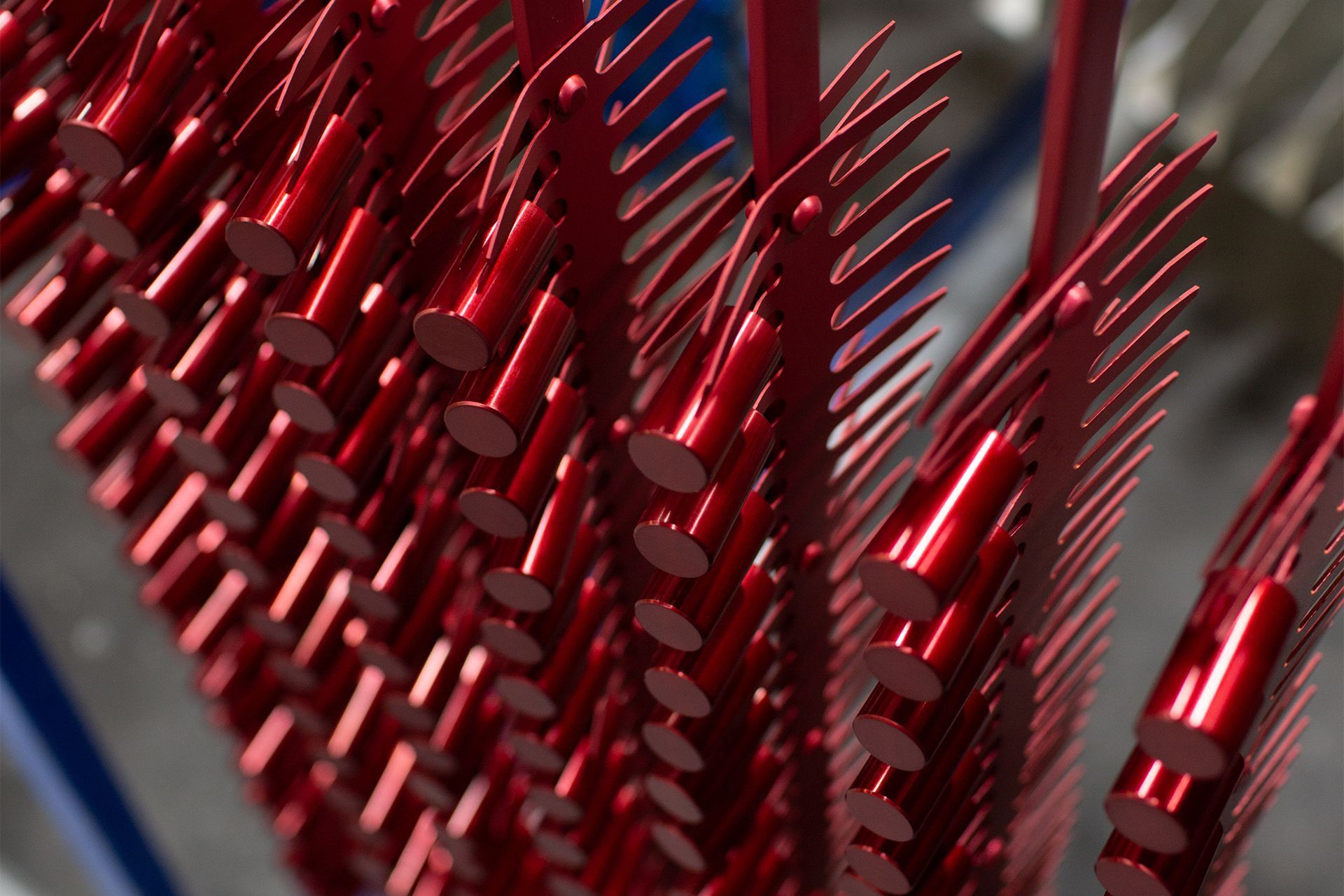

Anodizing Firearms to Prevent Rust

One of the most effective methods of preventing rust on firearms is anodizing. Anodizing is an electrochemical process that converts the surface of metal components into a durable, corrosion-resistant layer. This process is especially suited for aluminum parts commonly used in firearms, as it strengthens the metal's natural resistance to rust and wear.

Anodizing Process

The anodizing process involves immersing aluminum parts in an electrolyte solution, typically sulfuric acid, and then passing an electric current through the solution. This causes a controlled oxidation of the metal surface, forming a protective oxide layer that is integrated into the metal itself. This oxide layer is not only incredibly durable but also highly resistant to corrosion, making it an ideal choice for firearm maintenance and care.

Benefits of Anodizing

Anodizing offers a range of benefits, making it one of the most popular finishing methods for firearm components. The anodized layer is incredibly resistant to corrosion, providing long-lasting rust prevention. Anodizing can be used to create a variety of colors and finishes, allowing gun manufacturers to customize the appearance of their products without sacrificing durability.

Anodizing vs. Other Metal Finishes

While anodizing is one of the best methods for protecting firearm components from rust, there are several other metal finishing techniques available, each with its own set of limitations.

Powder coating provides a durable layer on metal surfaces but lacks the long-term corrosion resistance of anodizing and can chip over time. Electroless nickel plating is highly corrosion-resistant but comes with higher costs and less versatility than anodizing. Bluing offers basic rust protection but requires regular maintenance and isn’t as durable or effective as anodizing for modern firearms.

Superior Corrosion Resistance

When comparing these finishes, anodizing stands out as the most corrosion-resistant option for aluminum firearm parts. Unlike powder coating or bluing, anodizing provides a deep, integrated oxide layer that protects the metal from moisture and rust, making it the top choice for firearm business owners and gun part manufacturers looking for reliable, long-term rust prevention.

Durability and Maintenance

Anodized firearm components are known for their exceptional durability as the anodizing process creates a hard, protective layer resistant to scratches, wear, and corrosion. Unlike other finishes that may require regular maintenance or touch-ups, anodized parts keep their integrity over the years and reduce the need for frequent refinishing.

Aesthetic and Functional Benefits

Not just for rust protection, the anodized layer can be dyed in a variety of colors, offering gun manufacturers the ability to create custom-finished products. Anodized parts retain their lightweight properties, making them suitable for performance-driven firearms where weight is a consideration.

Why Partner with Light Metals Coloring

Light Metals Coloring (LMC) specializes in anodizing services for the firearms industry, providing expertise and quality that business owners and manufacturers can rely on. With decades of experience, LMC offers anodizing solutions tailored to meet the specific needs of the firearms market. Our process ensures superior rust prevention, durability, and aesthetic appeal, all while maintaining the highest industry standards. Whether you are a gun shop owner, part manufacturer, or firearm professional, our anodizing solutions are tailored to meet your business needs.

Don't leave your firearms vulnerable — contact LMC today to learn more about how our professional anodizing services can help preserve and protect your firearms for years to come.