Aluminum vs. Stainless Steel: A Guide to Sustainable Metal Choices

In our increasingly eco-conscious world, the sustainability of materials used across various industries is critical. Here, we’ll examine two prominent metals, aluminum and stainless steel, focusing on their environmental impacts, recyclability, and overall sustainability. As we discuss whether aluminum is eco-friendly and understand the eco-friendliness of stainless steel, our goal is to give you the knowledge needed to make informed decisions regarding your metal finishing choices.

Understanding the Sustainability of Metals

Sustainability in metal production involves more than just end-of-life recycling; it begins with the extraction of raw materials and extends through to the manufacturing processes. Key factors include the recyclability of the metal, the energy consumed during production, and the overall carbon footprint. Making sustainable choices is crucial not only for industry stakeholders but also for individuals seeking eco-friendly lifestyle options.

Environmental Impacts of Aluminum Production

Aluminum production is known for its high energy requirements, particularly in the initial smelting process. However, strides toward sustainability are being made by adopting renewable energy sources, which help reduce the carbon footprint. Despite its energy-intensive production, aluminum offers significant long-term benefits due to its lightweight nature, corrosion resistance, and its wide range of applications in eco-friendly projects.

Environmental Impacts of Stainless Steel Production

Stainless steel production is resource-intensive, involving extensive mining and energy consumption. However, with its strength and durability, products made from stainless steel tend to have longer lifespans, reducing the need for frequent replacement, which mitigates some of the initial environmental costs. It’s important to note that Light Metals Coloring does not offer stainless steel finishes, focusing instead on more sustainable aluminum solutions.

Recyclability and Circular Economy

Both aluminum and stainless steel boast high recyclability rates and play a pivotal role in the circular economy. Recycling aluminum can save up to 95% of the energy required to produce it from raw materials. Both metals retain their properties indefinitely when recycled, preventing the need for additional resource extraction and reducing overall environmental impact.

Energy Efficiency in Use and Transportation

Aluminum’s lightweight nature significantly increases its energy efficiency, particularly in transportation applications. This can lead to reduced fuel use and lower greenhouse gas emissions. In contrast, the heavier weight of stainless steel can increase energy consumption during transport.

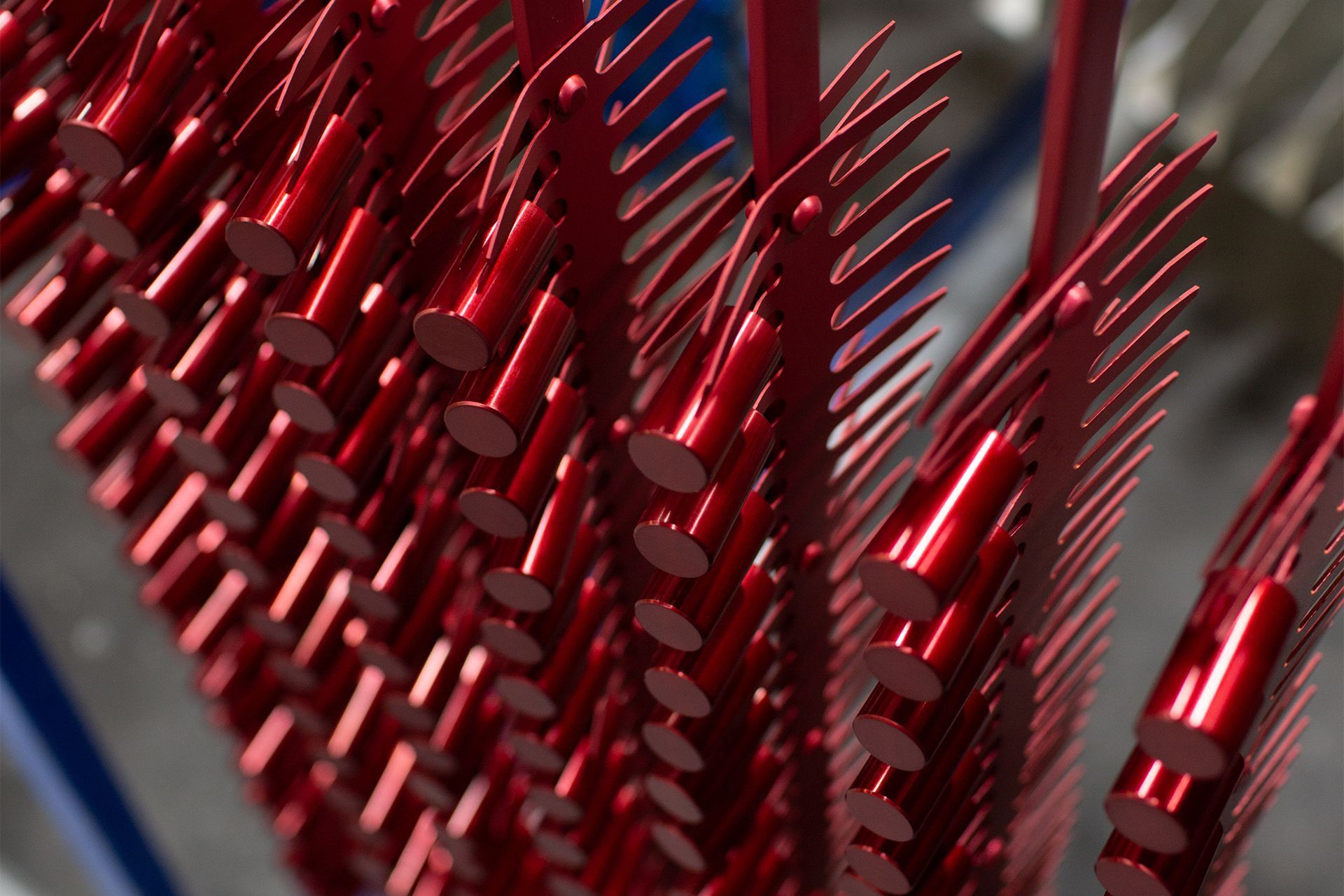

Making the Sustainable Choice with LMC

Choosing the right metal for your needs involves weighing these sustainability factors. For those prioritizing energy efficiency and high recyclability, aluminum is the recommended choice. Light Metals Coloring specializes in aluminum finishes, ensuring that your projects meet aesthetic and functional requirements while contributing to a more sustainable planet.

Committing to Eco-Friendly Metal Selection

With a firm understanding of the environmental impacts and sustainability attributes of aluminum and stainless steel, you're equipped to make informed and responsible choices. At Light Metals Coloring, we're dedicated to helping you choose the best eco-friendly metal solutions, talk to our team today to learn more.