Four Factors That Affect Anodizing Cost

Anodizing is a process that enhances the durability, corrosion resistance, and aesthetic appeal of aluminum and other metals. By creating an oxide layer on the surface, anodizing protects the metal while allowing for color customization and other surface treatments. Unsurprisingly, there are multiple factors influencing anodizing costs, but understanding these factors can allow a business to make budget considerations for anodizing.

Understanding the Anodizing Process

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant anodic oxide finish. The process typically involves immersing the metal in an acid electrolyte bath and passing an electric current through it. The result is a protective layer that can also be dyed or finished in a multitude of ways. The anodized surface is integrated with the underlying aluminum, meaning it won’t chip or peel, making it ideal for a wide range of applications, from aerospace components to decorative finishes.

What Affects Anodizing Cost?

1. Volume of Parts

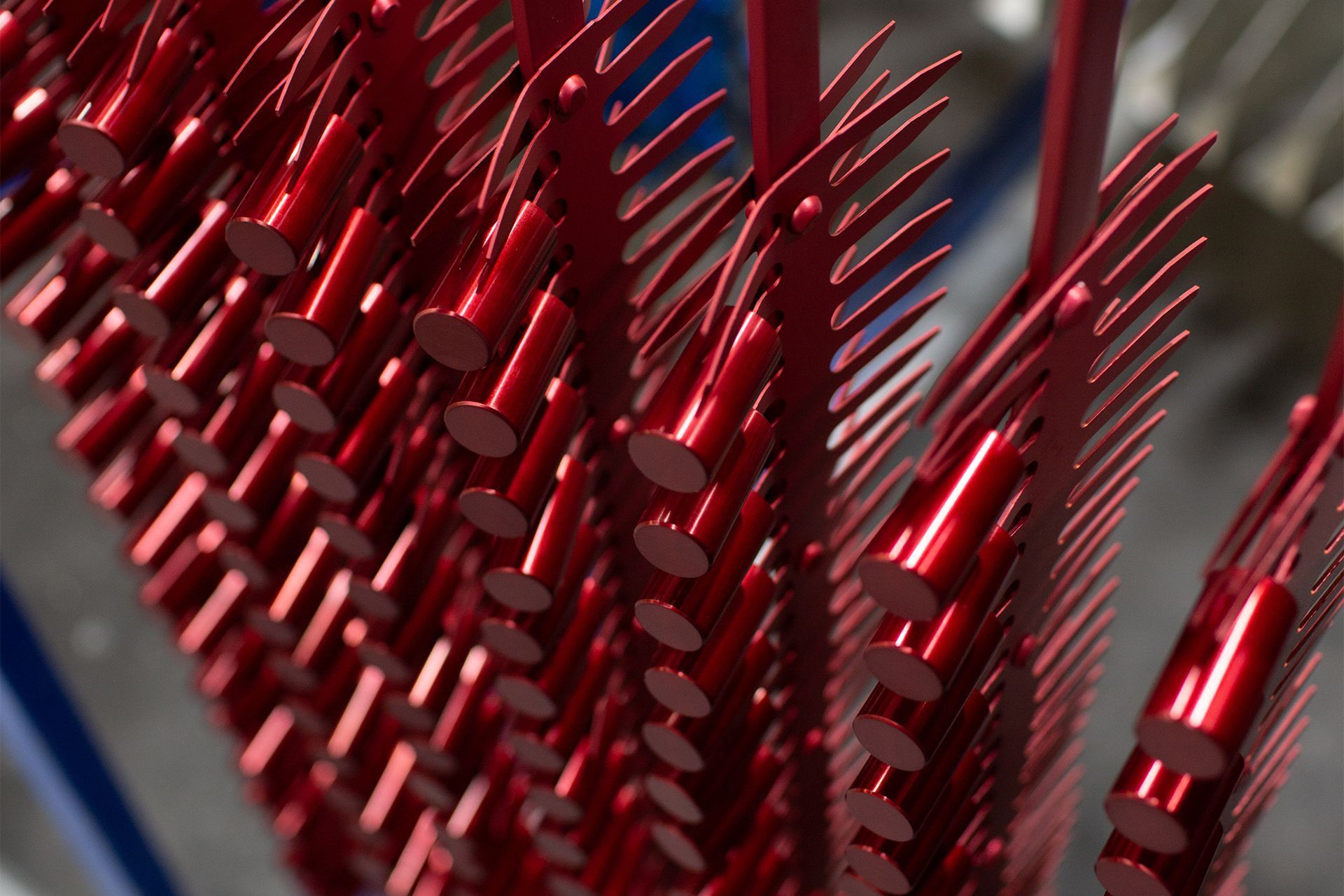

One of the anodizing pricing factors is the volume of parts being processed. Higher volumes can lead to reduced per-unit costs due to economies of scale. Anodizing companies will often offer a tiered pricing model with discounts leaning towards large orders as setup and processing times are spread across multiple units. Smaller orders, however, tend to have higher per-unit costs because the same setup and processing steps are still required, but for fewer parts.

A small batch of custom-machined parts may fetch a higher cost per piece compared to a bulk order of standard aluminum profiles. It’s important to consider how many parts are being anodized and whether it’s feasible to consolidate smaller orders into larger batches to save on costs.

2. Type of Anodizing Required

The specific type of anodizing you need can also affect the overall cost, with the most common types of anodizing including:

- Type I (Chromic Acid Anodizing): Offers a thin, highly corrosion-resistant coating, used often in aerospace applications.

- Type II (Sulfuric Acid Anodizing): This is the most common type and allows for color dyeing, popular for architectural and consumer products.

- Type III (Hard Anodizing): Provides a much thicker, harder layer that is ideal for heavy-duty industrial applications.

The cost factors for anodized aluminum vary based on the type chosen. Type III anodizing, for instance, requires more time and energy to create the thicker oxide layer, leading to a higher cost. Specialized treatments or specific industry standards (such as military or aerospace certifications) may also increase the pricing.

3. Part Complexity and Size

Intricate geometries, small crevices, and delicate components require careful handling during the anodizing process to ensure even coverage. More complex parts may take longer to set up, process, and inspect, further driving up labor costs.

Larger parts or assemblies tend to be more expensive to anodize because they require larger tanks and more resources. Keep in mind that custom fixtures or tooling may be necessary to hold parts in place during the anodizing process which adds to the overall expense.

4. Additional Services and Customization

Beyond the basic anodizing process, several additional services and customizations can influence the total anodizing cost. Some parts may require cleaning, masking, or pre-treatment before anodizing, with masking being particularly important for parts with areas that need to remain anodized-free (such as threads or mating surfaces).

Customization options may raise the price, like choosing specific colors or finishes. While standard anodizing finishes are cost-effective, unique or custom colors can incur additional charges due to the special dyes and processes involved.

Practical Tips for Managing Anodizing Costs

For businesses looking to control anodizing costs, several strategies are available to lower expanses without sacrificing quality.

1. Optimize Order Quantities

Anodizing costs can decrease with larger orders due to economies of scale. To reduce the per-unit cost, consider grouping smaller projects into a larger order whenever possible. Discuss volume discounts with your anodizing provider and plan orders accordingly.

2. Choose the Right Anodizing Type

Carefully consider the type of anodizing you need based on your application. While Type III anodizing may provide superior durability, it might be overkill for parts that don't require a heavy-duty finish. Selecting a less intensive process, such as Type II anodizing, can offer sufficient protection and aesthetics while keeping costs in check.

3. Design for Efficiency

Part design plays a crucial role in the anodizing process. By simplifying part geometry and reducing the number of complex features, you can minimize handling and processing time. Lower costs by avoiding overly intricate designs and streamlining the anodizing process. Consulting with your anodizing provider during the design phase ensures that your parts are optimized for cost-effective processing.

4. Work with a Reliable Anodizing Partner

Working with a trusted anodizing provider can help ensure that you get the best value for your money. A reliable partner will work with you to identify cost-saving tips for anodizing while delivering high-quality results.

If you're ready to optimize your anodizing costs while ensuring

full compliance with industry standards, contact Light Metals Coloring to learn how we can help you achieve your goals within budget.