Questions to Ask Before Choosing a Metal Finisher

Metal finishing is an important process across a variety of industries. But what is the metal finishing process? It involves treating a metal part's exterior, typically by applying a specific type of coating, to improve corrosion-resistance, strength, and more. There are many types of metal finishing treatments, and the right one depends on the product and material you are working with.

Of course, with any important process comes the task of finding a high-quality provider. That’s why we’ve put together a list of key questions to ask before choosing a metal finishing partner. Let’s take a look! We’ll also cover what information a metal finisher will need from you before getting started. Being prepared with the right project details can help streamline the process, saving you time and ensuring a more efficient experience.

1. What Metal Finishing Services Do You Provide?

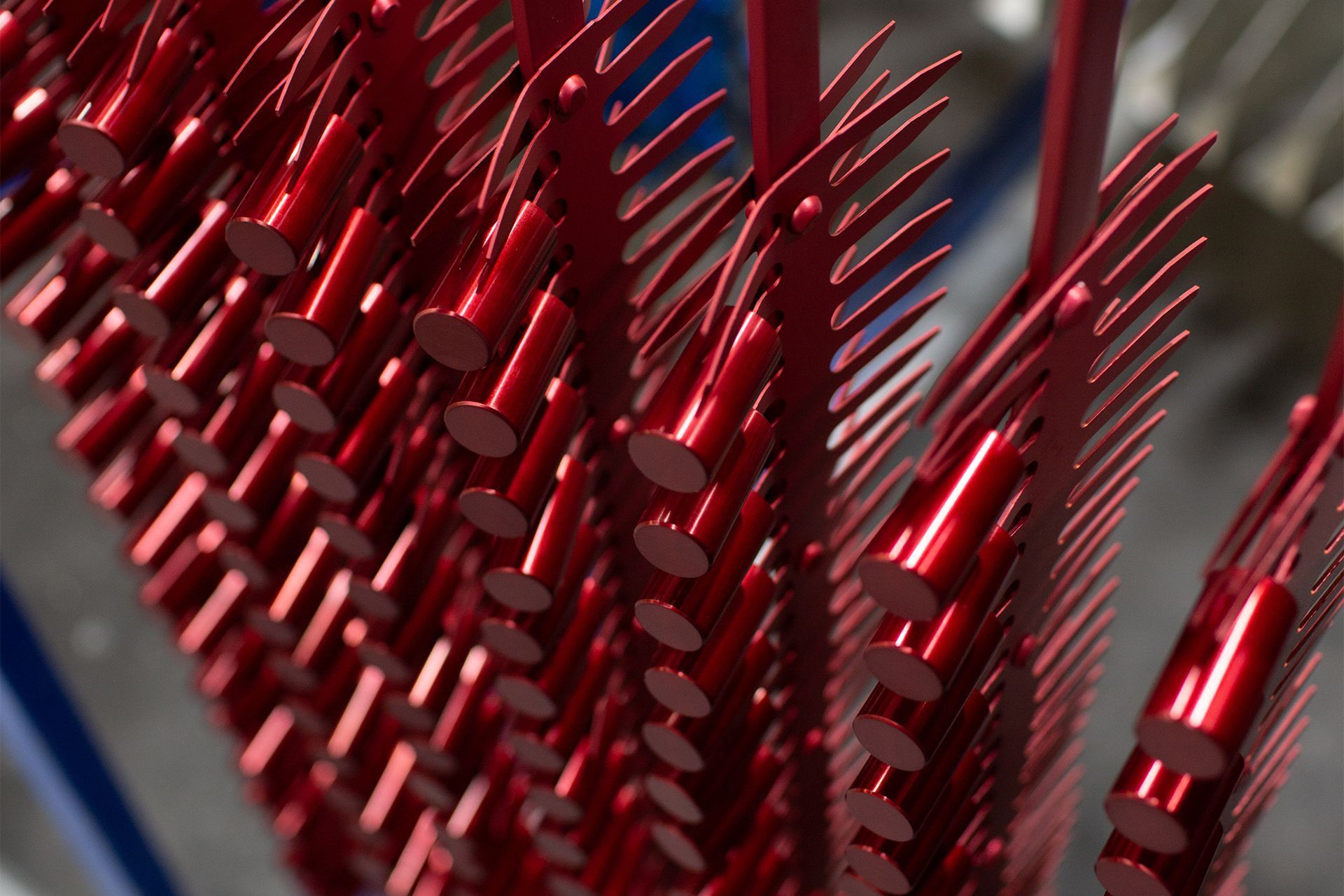

Metal finishing services are important for several reasons. First, they can help enhance a part or product’s lifespan, particularly when it comes to minimizing corrosion and wear. They can also have an impact on electrical properties, bonding, and aesthetics. Therefore, it’s crucial to know the capabilities of a prospective metal finishing provider before you begin to work with them. Some may only offer standard anodizing services, while others’ services may also include phosphating, laser-engraving, dry lubricant coatings, and more.

2. How Do You Guarantee Consistent Quality and Delivery?

No matter your industry or application, you need to ensure that you’ll be satisfied with the outcome of your metal finishing services time and time again. Inconsistent results could jeopardize the functionality of your products – and your business’s reputation. Consistent quality and delivery of metal finishing services are some of the most important reasons why customers stay with their suppliers for years. You should expect a multitude of questions from a professional metal finishing company when onboarding new products. By obtaining a deep understanding of the product to be finished, the finisher will create the best solution for the customer’s expectation.

Tip: Be sure to ask about the company’s quality control measures, inspection processes, and testing capabilities. This will give you insight into how they maintain high standards across all finished products.

3. What Certifications Do You Currently Hold?

Any metal finisher should follow best practices and strive to meet regulatory requirements, standards, and practices. However, a quality finisher often takes things a step further to demonstrate a competitive advantage over the competition. This often comes in the form of third party certifications, which help reinforce professionalism and responsibility.

Look for management system certifications from NADCAP AC7004, ISO 9001 (for aerospace applications), or MIL-SPEC compliance for military and defense projects. These certifications ensure that the metal finisher meets rigorous industry standards and provides a high level of quality assurance.

4. Can You Design a Custom Solution For My Project?

A good metal finishing company should work to become an extension of its customers' businesses. That is, it should be looking to forge a lasting, mutually beneficial partnership. In the end, a metal finisher will only be as successful as the customers it works with.

Not all types of metal finishes are applicable to all parts and products. With this in mind, personalized, one-on-one service and a willingness to design custom solutions when necessary is a critical offering to look for when deciding on a metal finishing company.

In addition to custom services, it's important to select a metal finisher that is responsive, collaborative, and versatile. Not only should your finisher be experienced and qualified, but they should also work in a wide range of markets and industries. If you require specialized coatings or treatments for industries like medical, aerospace, or firearms, ensuring that the finisher has experience in those sectors can prevent costly missteps.

5. What Information Should I Provide to a Metal Finisher?

Before reaching out to a metal finisher, having detailed information about your project can help ensure a smooth and efficient process. Here are the key details a metal finisher will need to know:

- Material Type: What kind of metal are you working with? Different metals require different finishing processes.

- End-Use Application: How will the part be used? (e.g., high-temperature environments, exposure to chemicals, electrical conductivity needs).

- Required Finish Type: Do you need anodizing, phosphating, powder coating, or another specific finish?

- Dimensional Specifications: Are there tight tolerances that must be maintained during the finishing process?

- Quantity & Batch Size: Will this be a small run or a large-scale production order?

- Color & Aesthetic Requirements: If color consistency or branding is important, specify exact shades or finishes.

- Performance Expectations: Are there specific durability, corrosion resistance, or friction requirements?

- Compliance & Certification Needs: Does your project require industry-specific standards like MIL-SPEC, ISO, or NADCAP compliance?

- Delivery Timeline: When do you need the finished parts? Are there any critical deadlines?

By providing these details upfront, you can save time, avoid unnecessary back-and-forth communication, and receive a more accurate quote and timeline from your metal finishing provider.

Light Metals Coloring: Committed to Your Success

At Light Metals Coloring, we combine personalized service with years of finishing expertise to position ourselves as an extension of our partners' businesses and exceed their expectations.

We understand that efficiency is key, which is why we encourage customers to come prepared with key project details. Our team is ready to assist you in selecting the best metal finishing solutions tailored to your needs.

For more information about our metal finishing services and commitment to quality and compliance,

contact us today! We can also provide a custom quote for your project and connect you with a member of our team to discuss your needs.