What Happens to Your Parts During the Anodizing Process

Anodizing is a game-changer when it comes to increasing metal durability, corrosion resistance, and aesthetics. From aerospace to automotive or consumer products, anodizing plays a crucial role in extending the lifespan and performance of metal parts. But what actually happens during the anodizing process?

In this behind-the-scenes look, we'll break down each step, from pre-treatment to sealing, showing how precision and care ensure high-quality results every time.

Step-by-Step Breakdown: The Anodizing Process

Anodizing is an electrochemical surface treatment that converts the outer layer of aluminum into a durable, corrosion-resistant finish. This process not only strengthens the metal but also allows for custom coloring.

Let's walk through each step of the anodizing process and see how raw metal parts transform into high-performance, anodized components.

Step 1: Pre-Treatment – Surface Preparation

Before anodizing can begin, parts must go through meticulous surface preparation to remove contaminants and ensure a flawless finish.

- Cleaning: The metal is washed to remove oils, dirt, and residues from manufacturing or handling.

- Etching or Brightening: Depending on the desired finish, the surface is either etched for a matte look or brightened for a shiny appearance.

- Rinsing: A thorough rinse ensures the surface is pristine before moving to the next stage.

This step is crucial because any imperfections on the surface can impact the final anodized layer.

Step 2: The Anodizing Bath – Electrochemical Transformation

This is where the real magic happens!

- The parts are immersed in an acid electrolyte solution (usually sulfuric acid).

- An electric current is applied, causing the aluminum surface to oxidize and form a controlled anodic layer.

- The thickness of the anodized layer is carefully adjusted to match the part's intended application—thinner for decorative finishes, thicker for heavy-duty industrial use.

At this stage, the metal's surface becomes porous and ready for color absorption if desired.

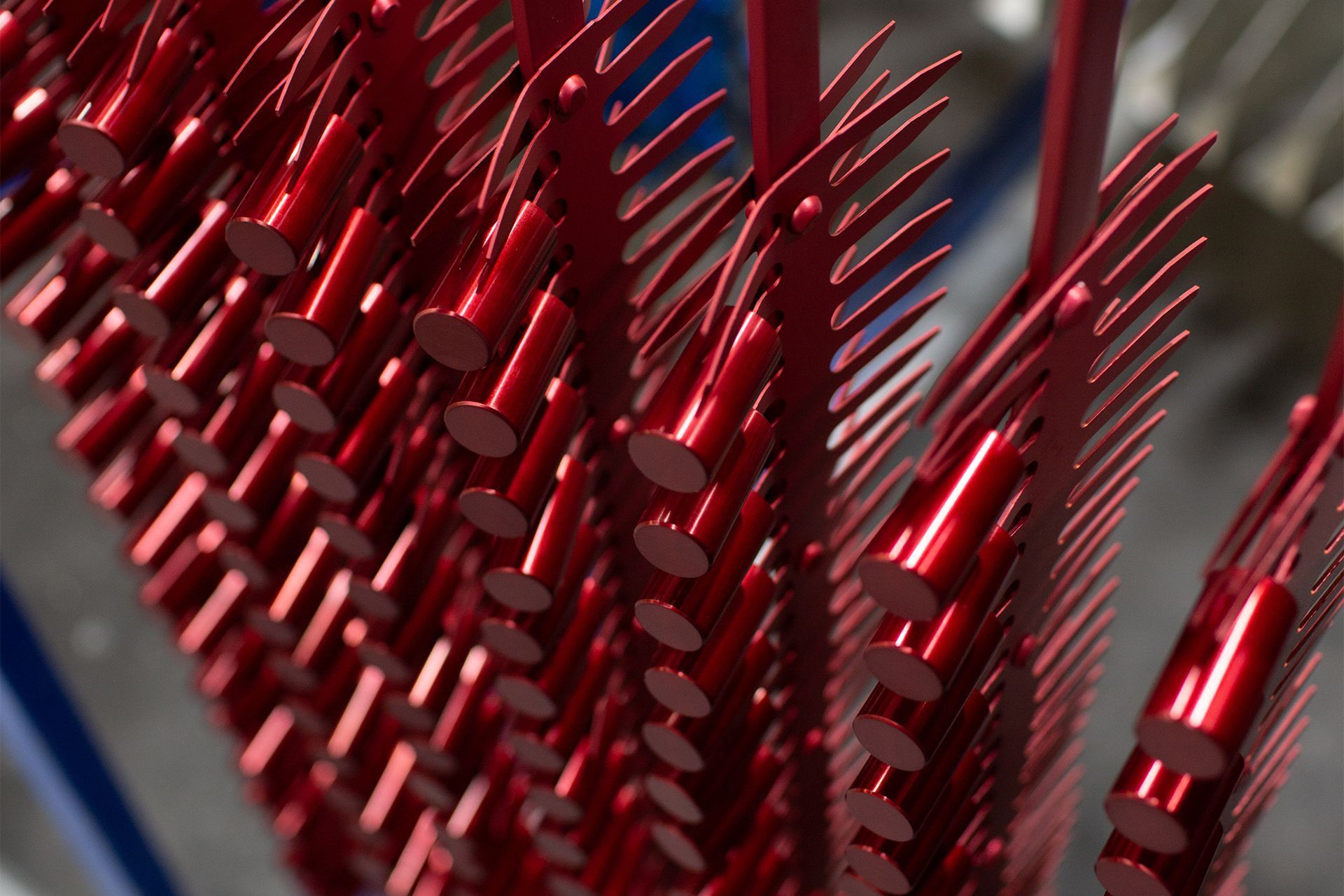

Step 3: Coloring (Optional but Popular)

One of the major benefits of anodizing is the ability to add custom colors to metal parts.

- How Dyeing Works: The porous anodized layer absorbs dyes, creating a vibrant, long-lasting finish.

- Color Options: Anodized aluminum can be finished in black, red, blue, gold, and many other shades, depending on the application.

- Sealing the Color: To lock in the color and prevent fading, the part goes through a sealing process

Step 4: Sealing – The Final Protective Touch

Sealing is the final step in the anodizing process, closing the pores of the anodized layer to increase corrosion resistance.

- Why Sealing Matters: Without sealing, the anodized surface remains porous and more susceptible to damage over time.

- Sealing Methods: Common methods include hot water sealing (which causes the anodic pores to swell and close) and nickel acetate sealing (which provides additional wear resistance).

This step ensures that anodized parts remain strong, corrosion-resistant, and visually appealing for years to come.

Quality Control & Inspection

At Light Metals Coloring, quality control is a top priority. Every anodized part undergoes rigorous inspection to ensure it meets precise industry standards. The first step in the process is thickness measurement, which verifies that the anodic layer has been applied correctly for the required level of durability. Next, adhesion testing ensures that the anodized coating is firmly bonded to the metal surface, preventing peeling or flaking over time. Finally, each part goes through a detailed visual inspection, where specialists check for any surface imperfections or inconsistencies.

Common Questions About Anodizing

Does anodizing change part dimensions?

Slightly. Anodizing adds a thin layer to the metal surface, but it is typically measured in microns and does not significantly affect part dimensions.

How long does an anodized coating last?

With proper sealing and maintenance, anodized coatings can last for decades, providing superior wear and corrosion resistance.

Can anodized parts be repaired or re-anodized?

Yes! Worn or damaged anodized surfaces can often be stripped and re-anodized, restoring their original protection and appearance.

Are there any downsides to anodizing?

While anodizing is highly beneficial, it is mainly suited for aluminum and a few other metals. Additionally, some extreme conditions (like exposure to strong alkalis) can degrade the anodized layer over time.

Why Trust the LMC Anodizing Process?

At LMC, anodizing is more than just a process—it’s a precision-driven craft backed by decades of expertise, state-of-the-art facilities, and tailored solutions for industries like aerospace, medical, and industrial manufacturing. Our commitment to quality, durability, and stunning finishes ensures that every part meets the highest standards.

Now that you've seen the care and precision behind our anodizing process, you can trust LMC to deliver exceptional results every time. Ready to get started? Contact us today and

learn more about our services!