The Future of Metal Finishing and Technology

The metal finishing industry has undergone a remarkable transformation, evolving from small “mom-and-pop” shops into a lucrative, innovation-driven sector. Once a niche market dominated by family-run businesses, the industry now attracts private equity investments eager to capitalize on its scalability and profitability.

This surge in financial backing has fueled technological advancements, making metal finishing a critical component in modern manufacturing. We’ll explain cutting-edge metal coating technologies, industry trends, and how private equity investments are reshaping the future of metal finishing.

From Mom-and-Pop Shops to an Industry Revolution

Historically, the metal finishing industry thrived through small, family-owned businesses. These shops built a reputation for craftsmanship and personalized service but often faced limitations in scalability and resource access. However, private equity firms have recognized the industry’s untapped potential.

Investors see metal finishing as a “cash-printing” industry due to its essential role in manufacturing durable, high-performance components for

automotive,

aerospace,

electronics, and

industrial applications. With consistent demand for corrosion-resistant, long-lasting finishes, the industry offers scalable growth with significant returns. By infusing capital into small operations, private equity firms have transformed many into large-scale enterprises with cutting-edge capabilities.

Emerging Metal Coating Technologies

Technological advancements in metal finishing are driving industry innovation. The

development of high-performance coatings has expanded possibilities for manufacturers seeking durable and efficient solutions. Some of the most promising advancements include:

- Nanotechnology-Based Coatings: These coatings increase surface properties such as corrosion resistance, hardness, and friction reduction at a microscopic level.

- Eco-Friendly Coatings: As environmental regulations tighten, manufacturers are adopting coatings with reduced environmental impact, including water-based and low-VOC finishes.

- Self-Healing Materials: Innovations like self-healing coatings can repair surface damage automatically, extending product lifespans and reducing maintenance needs.

- Advanced Thermal Sprays: These coatings offer superior heat resistance, making them ideal for high-temperature applications such as turbine blades and automotive exhaust systems.

These advanced metal coating technologies are setting new performance benchmarks across multiple industries.

Trends Shaping the Future of Metal Finishing

Several trends are redefining the metal finishing industry, emphasizing efficiency, sustainability, and technological integration:

- Automation and Robotics: Automated systems are boosting precision, reducing labor costs, and ensuring consistent quality.

- AI-Driven Quality Control: Artificial intelligence amplifies inspection processes, identifying defects faster and more accurately.

- Sustainable Practices: Companies are prioritizing eco-friendly processes, including waste reduction, recycling, and energy-efficient operations.

- Industry 4.0 Integration: The rise of smart factories leverages the Internet of Things (IoT) and real-time data monitoring for optimized production workflows.

- Predictive Maintenance: Data-driven maintenance systems help manufacturers reduce downtime and increase production efficiency.

These trends are enabling manufacturers to achieve greater scalability and profitability while minimizing environmental impact.

The Role of Private Equity in Driving Innovation

Private equity investment has played a pivotal role in advancing metal finishing technologies. Through strategic acquisitions and funding for research and development, private equity firms have accelerated industry innovation.

Notable examples include partnerships between private equity-backed companies and research institutions focused on developing next-generation coatings. These collaborations have led to breakthroughs in wear-resistant coatings, anti-corrosion technologies, and surface enhancements tailored for extreme environments.

The influx of capital has enabled companies to scale operations, adopt state-of-the-art equipment, and boost product quality, giving them a competitive edge in a rapidly evolving market.

Benefits of High-Performance Metal Finishing Technologies

Adopting advanced metal finishing technologies offers substantial benefits, including:

- Extended Product Lifecycles: High-performance coatings increase durability and resistance to environmental stressors, reducing wear and tear.

- Reduced Maintenance Costs: Durable finishes minimize the need for repairs and replacements, lowering operational expenses.

- Better Performance: Advanced coatings provide superior performance in harsh environments, meeting the demands of industries such as aerospace and defense.

- Greater Aesthetic Appeal: Modern coatings allow for customized finishes that improve product appearance while offering protective benefits.

These advantages create value not only for manufacturers but also for end-users and investors seeking long-term returns.

Challenges and Opportunities in the Evolving Metal Finishing Industry

While the future of metal finishing is promising, the industry still faces challenges, including:

- High Upfront Costs: Investing in new technologies and equipment requires significant capital, posing a barrier for smaller firms.

- Regulatory Compliance: Understanding complex environmental and safety regulations can be time-consuming and costly.

- Skilled Labor Shortages: As the industry becomes more technologically advanced, the demand for skilled technicians and engineers grows.

- Global Supply Chain Disruptions: Recent global events have emphasized the need for more resilient supply chains.

Despite these hurdles, the industry is ripe with opportunities, including expanding into emerging markets, leveraging sustainability initiatives, and capitalizing on the increasing demand for advanced metal finishes.

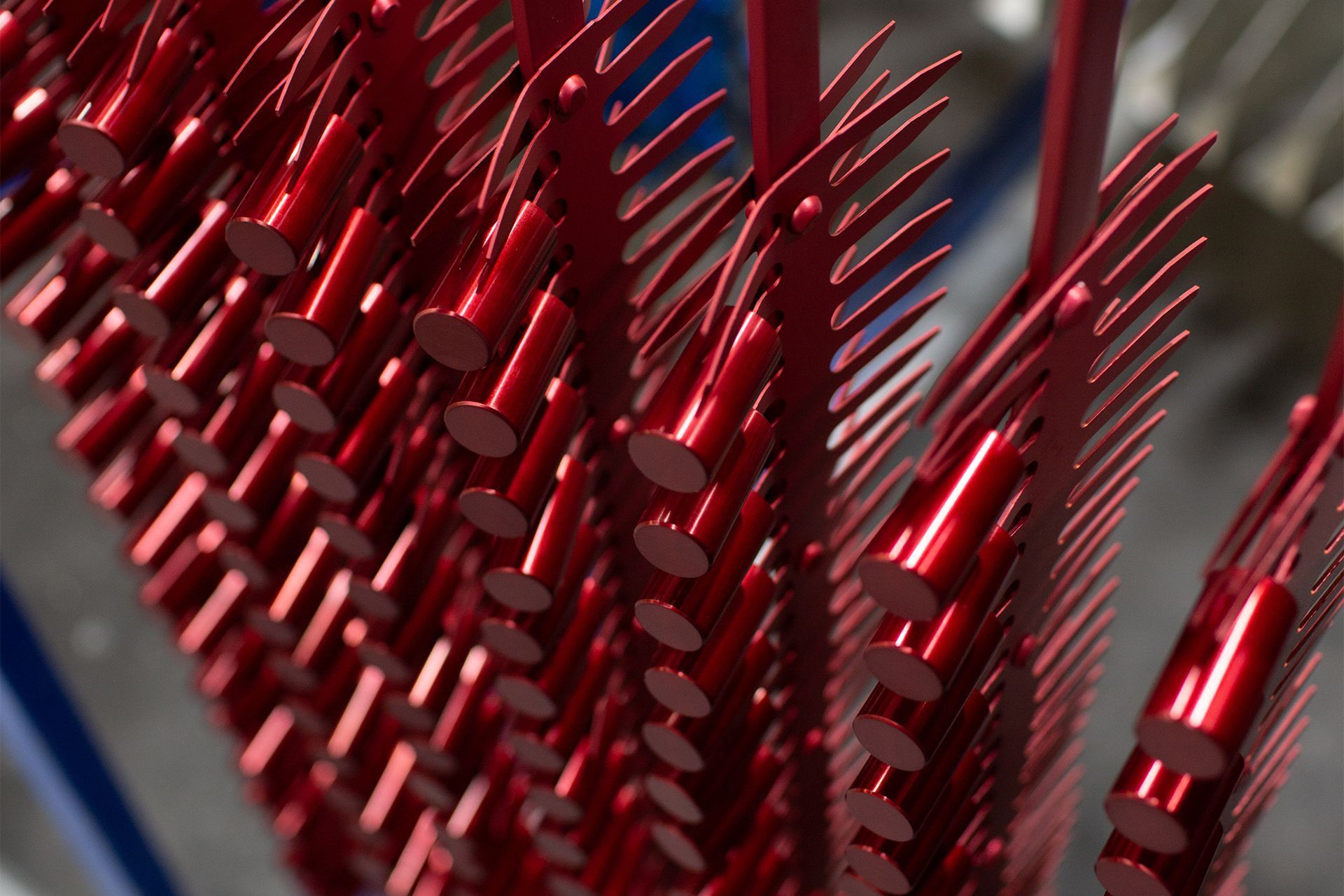

Leading the Charge in Metal Finishing Innovation

The metal finishing industry has evolved from small-scale operations to a highly profitable, innovation-driven sector. Thanks to technological advancements and

private equity investment, the industry continues to push boundaries with high-performance coatings and cutting-edge technologies.

At Light Metals Coloring (LMC), we remain committed to leading the charge in

metal finishing innovation. Unlike companies seeking acquisition, we are here to stay—dedicated to delivering industry-leading solutions that drive success for manufacturers and investors alike. Stay informed about emerging technologies and industry trends to remain competitive in this ever-evolving market!