Bulk vs. Rack Anodizing: Pros, Cons, & Differences

In metal finishing, the choice between different anodizing methods is crucial. Two common methods used to anodize parts are bulk anodizing and rack anodizing. This guide provides a detailed examination of these two primary techniques, highlighting their individual advantages, limitations, and key differences. Through this analysis, we aim to equip readers with the knowledge needed to make informed decisions based on their specific requirements. Let's delve into the characteristics and considerations of each anodizing method.

What is Bulk Anodizing?

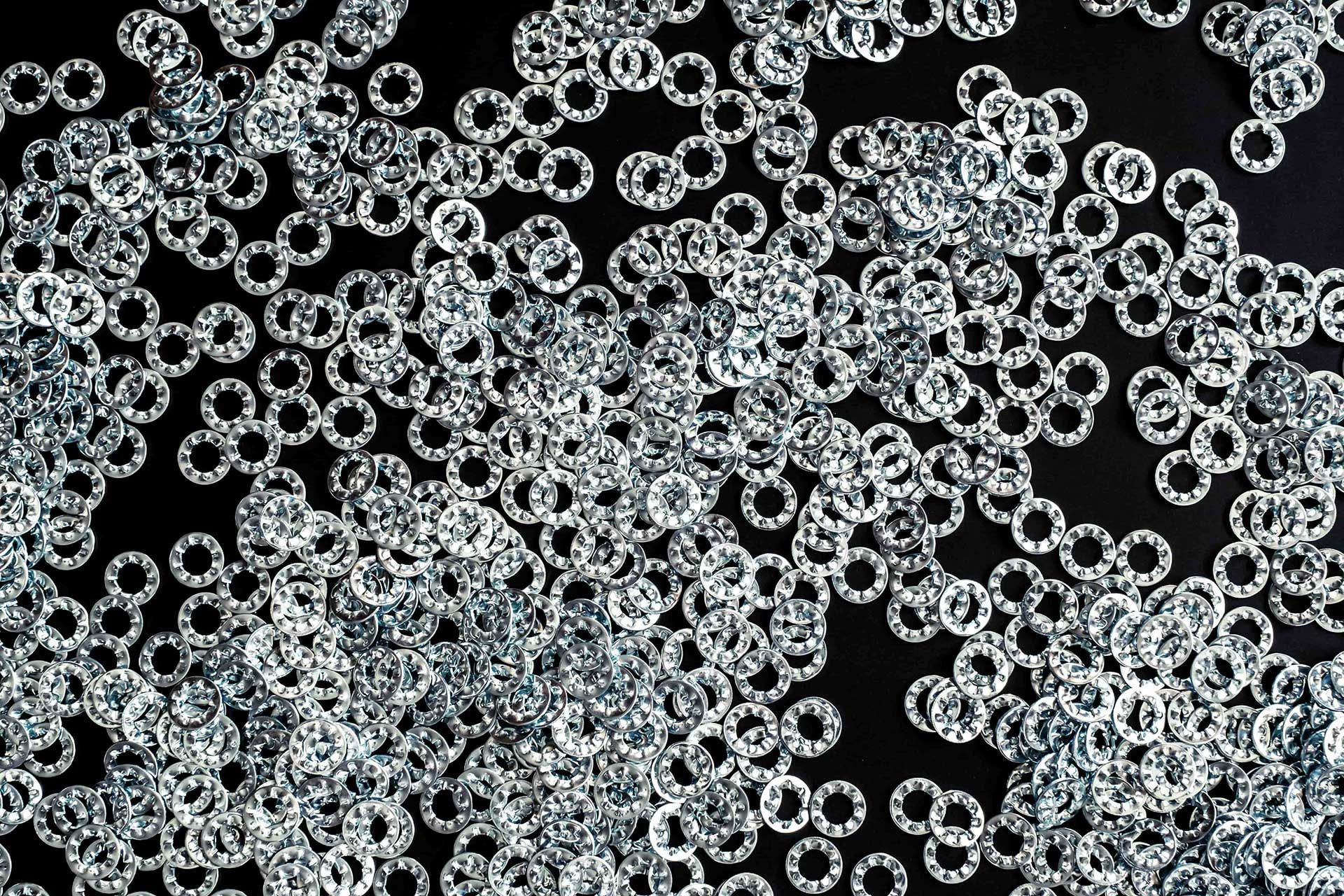

In the metal finishing industry, bulk anodizing refers to the process where metal parts are simultaneously anodized by submerging them collectively in a specialized chemical bath. This process, favoring large production batches, allows for a more streamlined and cost-effective approach compared to techniques like rack anodizing, where each part is processed individually. By treating numerous parts together, bulk anodizing ensures consistent finishes, particularly beneficial for industries prioritizing uniformity. However, it's essential to note that this method does have limitations when handling complex or varied parts.

What is Rack Anodizing?

Rack anodizing is a method wherein individual metal parts are meticulously mounted on racks and then submerged in a chemical bath. Rack anodizing allows for precise control, accommodating parts with irregular shapes or specific processing requirements. This technique is especially suitable for parts demanding selective anodizing or those of diverse sizes. While rack anodizing offers enhanced flexibility and precision, it may be more labor-intensive and can sometimes present challenges in ensuring consistent finishes across larger batches.

Pros of Bulk Anodizing

Cost-Effective for Large Quantities

Bulk anodizing is highly efficient for large production runs. This method involves immersing multiple parts into a chemical anodizing bath simultaneously, which can significantly reduce the processing time and labor costs per unit. It's especially advantageous when you have a substantial quantity of parts that are similar in size, shape, and anodizing requirements.

Consistent Finish

Because multiple parts are anodized together in the same bath, they tend to receive a consistent finish in terms of color, texture, and thickness of the anodized layer. This consistency is crucial for industries where uniform appearance and performance are essential, such as fastening, cosmetic or automotive manufacturing.

High Throughput

Bulk anodizing tanks are typically large and designed to accommodate a high volume of parts. As a result, this method offers a higher throughput compared to rack anodizing. This increased throughput can be critical for meeting production deadlines and minimizing lead times.

Reduced Labor Costs

Bulk anodizing requires less manual handling of individual parts during the anodizing process. This reduction in labor-intensive tasks like loading and unloading racks can lead to cost savings.

Cons of Bulk Anodizing

- Limited Size and Shape Flexibility: Bulk anodizing may not be suitable for large or complex-shaped parts, as they may not fit into the tanks or may be difficult to process in bulk.

- Potential for Part Damage: Parts can come into contact with each other during the bulk anodizing process, which may result in surface scratches or other damage if not properly handled.

- Lack of Precision: Achieving precise masking or selective anodizing is more challenging with bulk anodizing, making it less suitable for applications requiring intricate designs or patterns.

- Un-anodized material: because the process relies on part-to-part contact, bulk anodizing naturally yields unacceptable parts that did not make contact through the entire process, leading to fallout typically between 3 and 10% depending on the part configuration.

Pros of Rack Anodizing

Customized Processing

Rack anodizing is particularly well-suited for parts with irregular shapes, sizes, or configurations that cannot be efficiently bulk-processed. Each part is individually mounted on a rack, allowing for precise control over the anodizing process, which is vital when dealing with intricate or complex components.

Variety of Sizes

Unlike bulk anodizing, which works best with similar-sized parts, rack anodizing can accommodate a wide range of part sizes, making it versatile for small-scale production or parts with diverse dimensions.

Selective Anodizing

Rack anodizing permits selective anodizing of specific areas on a part. This capability is crucial when only certain sections of a component require anodizing, leaving other areas untouched or masked. Industries like electronics and telecommunications often use rack anodizing for this reason, as it allows for precise control over which areas are anodized and which remain bare.

High-Quality Finish

Because each part is individually processed and controlled during rack anodizing, it can often produce a higher-quality finish compared to bulk anodizing. This is particularly important for applications where surface aesthetics, corrosion resistance, and electrical conductivity are critical.

Less Material Interaction

Rack anodizing eliminates the risk of parts coming into contact with each other, which can lead to surface damage or imperfections. This is especially beneficial when dealing with delicate or high-value components

Cons of Rack Anodizing

- Higher Labor Costs: Rack anodizing can be labor-intensive since each part must be individually loaded onto racks, increasing processing time and labor costs.

- Lower Throughput: Due to the individual handling of parts, rack anodizing is generally slower and less efficient than bulk anodizing, making it less suitable for high-volume production.

- Potential for Inconsistency: Achieving uniform coatings on parts in rack anodizing can be more challenging, especially when dealing with a large number of racks, as variations in the anodizing process can occur.

How to Choose Between Bulk and Rack Anodizing

The choice between bulk anodizing and rack anodizing depends on factors such as the volume of parts to be processed, part size and shape, the need for precise masking, and cost considerations. Bulk anodizing is typically more cost-effective and efficient for high-volume, uniform parts, while rack anodizing offers greater flexibility and precision for smaller quantities and parts with specific requirements. Given the nuances of each method, it's prudent to consult with an

anodizing specialist. Their expertise can guide you in determining the optimal anodizing technique tailored to your metal part's unique needs.