Celebrating LMC’s NADCAP Recertification - A Testament to Excellence

LMC is delighted to announce that we have successfully renewed our NADCAP accreditation for an impressive 18 years in a row. This noteworthy milestone signifies almost two decades of unwavering dedication to upholding the highest standards of quality and reliability in our processes.

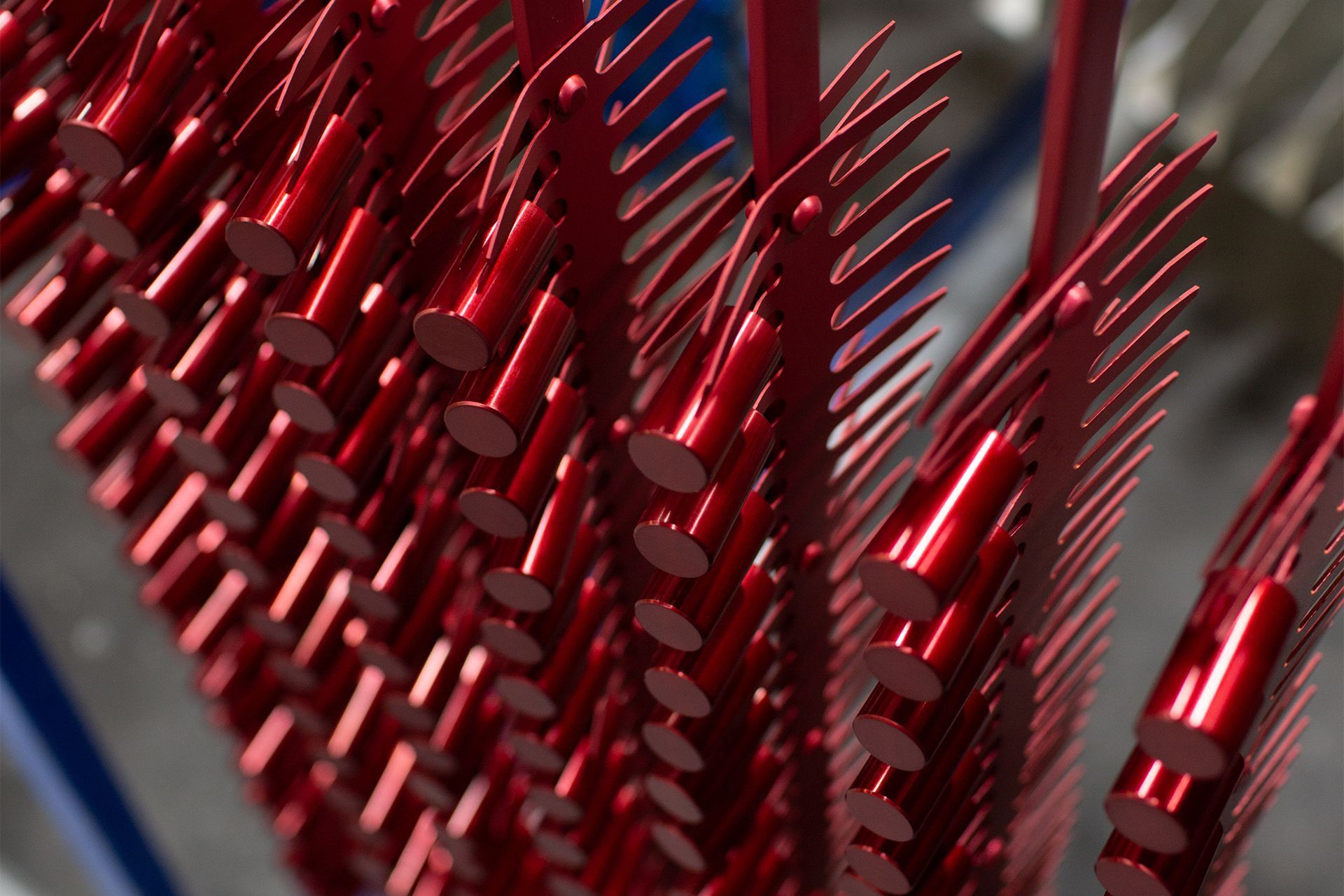

The NADCAP certification is not just a badge; it is an industry-recognized validation of our capabilities, expertise, and process controls in providing metal finishing solutions. Throughout the years, NADCAP has been a cornerstone of our business success. This accreditation has enabled us to gain the trust of prominent clients and partners within the aerospace and defense sectors. Our ability to meet and achieve merit status to NADCAP's strict requirements has helped us secure critical projects, propelling our growth and reputation in the industry.

At LMC, we understand the gravity of our role in ensuring the integrity and longevity of aerospace components. The aerospace industry is one where precision and safety are of utmost importance. The NADCAP certification allows us to constantly improve our methods, stay up-to-date with the latest technology, and make sure our processes meet the highest quality standards.

We owe this remarkable accomplishment to the collective efforts of our skilled and dedicated team members. Their relentless pursuit of excellence and adherence to NADCAP's rigorous guidelines have been instrumental in securing this recertification.

Furthermore, this achievement was only possible with our esteemed clients' and partners' trust and support. We are genuinely grateful for your ongoing faith in LMC, which motivates us to raise the bar and strive for perfection in every project we undertake.

As we look ahead, we are determined to uphold the principles that have brought us this far. Our commitment to NADCAP standards will continue to drive our actions and decisions, ensuring we remain an indispensable partner for your critical metal finishing needs.

Our sincere thanks go out to each and every one of you for being part of our journey. The NADCAP re-certification is a landmark achievement that underscores our commitment to excellence. We are enthusiastic about the journey ahead, as we build upon this accomplishment to deliver unparalleled quality and service.