Firearm Finish Types: How To Choose the Most Durable Gun Finish

In the firearm industry, the finish isn't just about aesthetics — it's about protection, performance, and longevity. Whether you're a business owner or parts manufacturer, choosing a durable gun finish can significantly enhance the life and functionality of your weapons. But you don't have to sacrifice the appearance for protection.

The Importance of a Durable Firearm Finish

A durable firearm finish is essential for several reasons. First, it provides corrosion resistance, which is crucial for maintaining the integrity of the firearm under various environmental conditions. A robust finish also helps preserve the firearm's aesthetic appeal, ensuring it looks as good as it performs. Moreover, an effective finish enhances the firearm's overall performance by reducing friction and wear on moving parts.

Firearm Finish Types

Different firearm finish types offer various levels of protection and aesthetic appeal. Depending on the component and the material it is made from, you have many different options available, depending on what you are looking to achieve.

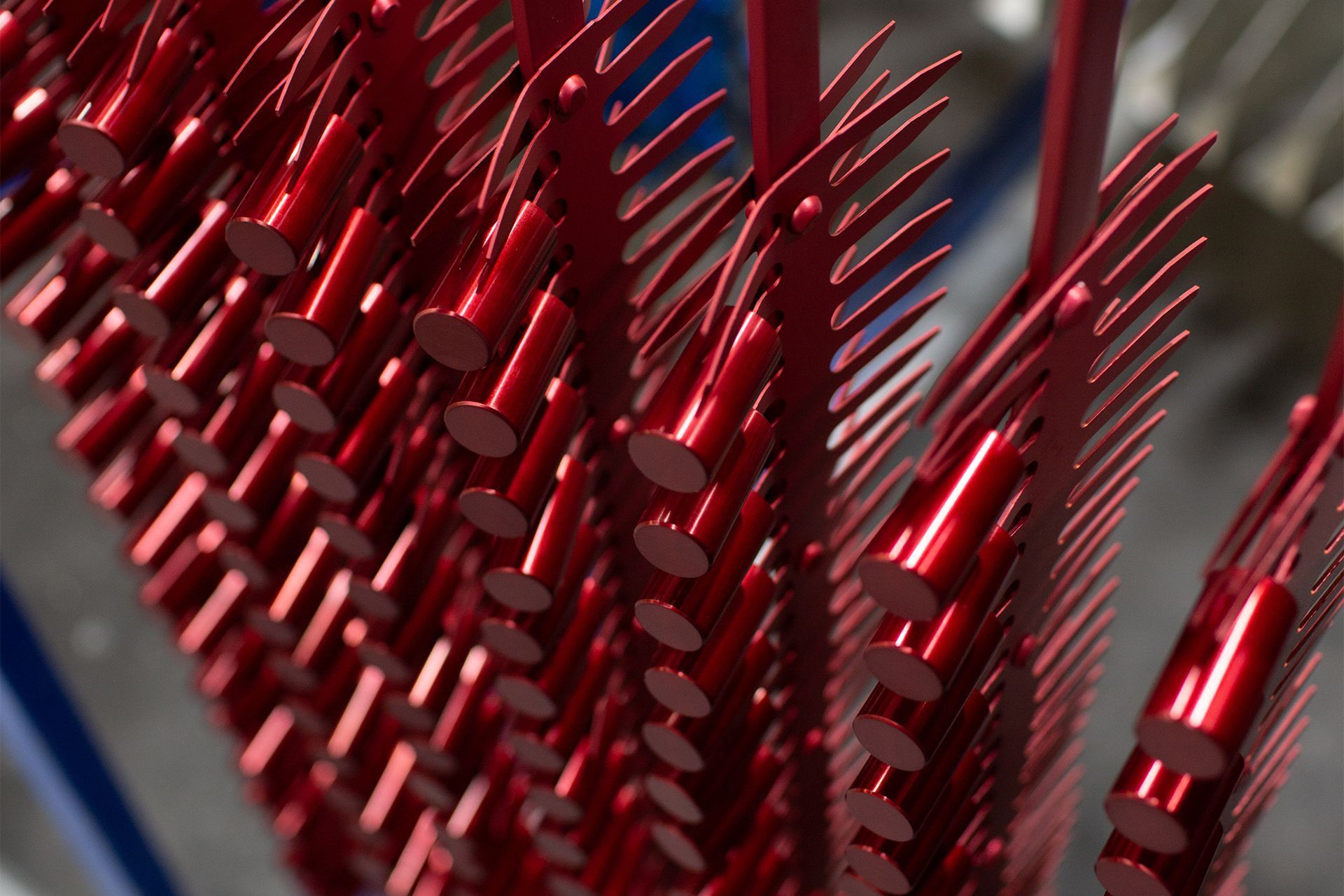

Hard Coat Anodize

Hard coat anodizing is an electrochemical process that produces a tough and corrosion-resistant surface on aluminum components. Commonly used on aluminum firearm parts, this finish offers a lightweight yet tough option. The benefits of hard coat anodizing include excellent wear resistance, availability in various colors, and a significant enhancement of the metal's wear resistance and corrosion protection. For those looking to invest in a durable firearm part, hard coat anodizing stands out as a go-to method for creating resilient and long-lasting firearms.

Cerakote

Cerakote is a polymer-ceramic composite coating known for its robustness and versatility. It’s used on a variety of materials, including metal, plastic, and wood. Cerakote offers resistance to abrasion, chemicals, and impact. Additionally, it allows for customizable colors and patterns, giving firearm owners both durability and aesthetic flexibility. For those debating between cerakote vs anodize, Cerakote is favored for its and visual customization and flexibility to be applied on more than just aluminum.

Chrome Plating

Chrome plating is widely used in the firearm industry on steel components for corrosion and wear resistance and reduced friction between moving parts. It is also a finish of choice for heat resistance for parts exposed to intense heat, as well as aesthetic appeal and ease of cleaning.

Chrome plating can withstand high temperatures without degrading, making it suitable for parts exposed to intense heat, such as barrels. Chrome-plated surfaces are smoother and less prone to fouling, making them easier to clean. This is particularly beneficial for components like barrels and bolt carriers.

Black Nitride

Black nitride, also known as ferritic nitrocarburizing, is used in the firearm industry for several reasons and can be used in place of Manganese phosphating in many cases. Enhanced wear and corrosion resistance, lubricity, thermal and dimensional stability, and the aesthetic appeal of a sleek matte black finish are a few reasons it is a finish of choice. The finish you choose should take the environment and usage into account to make the best choice.

Manganese Phosphate

Manganese phosphate, or parkerizing, is a chemical treatment that creates a crystalline coating on steel parts. This finish is widely used on military firearms for its strong anti-corrosion properties. The benefits of manganese phosphate include enhanced wear resistance, excellent oil retention, and a non-reflective surface.

How to Choose the Most Durable Gun Finish for Firearm Parts

Selecting the most durable finish for your firearm parts involves considering several factors, such as the firearm's material, the environment it will be used in, and the desired balance between aesthetics and functionality.

Consulting with LMC's metal finishing experts can provide invaluable insights tailored to your specific needs. Contact us today for personalized advice and top-tier finishing services. We can help determine whether anodizing, phosphate coating, or another metal finishing service is the best option for your firearm.