Case Study: Precision Forms - Purchase Orders In-Advance

The Opportunity

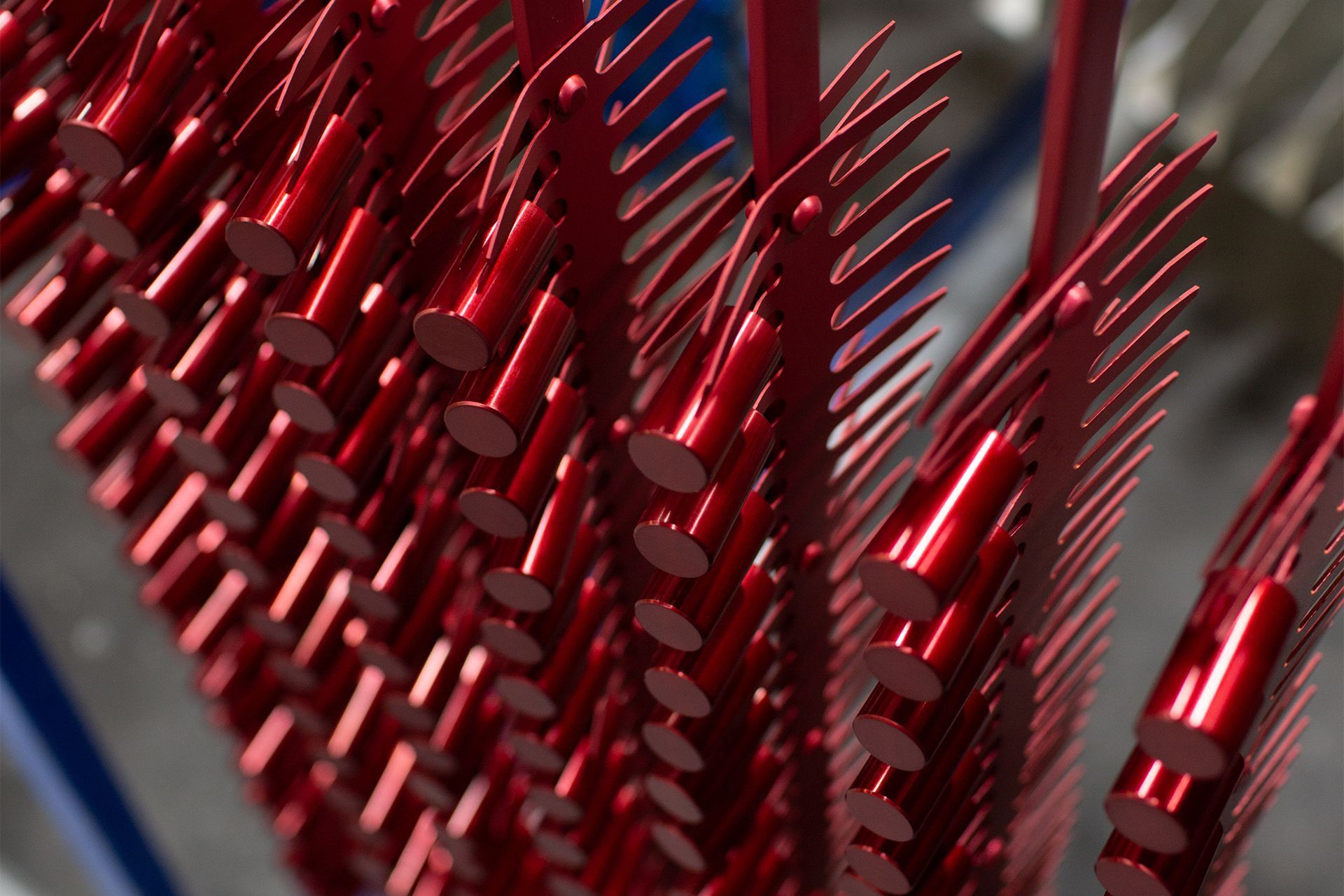

For decades, those in metal finishing or aluminum anodizing have been considered job shops, reacting to orders that show up on their dock with aggressive, sometimes past due, delivery dates. At Light Metals Coloring, the daily “surprises” and production inefficiencies were exhausting, costly and rarely yielded an outcome satisfactory to our clients.

You can especially imagine how things fared when a customer was in a pinch. Thankfully, we at LMC recognized the need to free ourselves from the constraints of a job shop operation, and the opportunity to do better for our customers. So when Precision Form Inc. came to us with an urgent delivery need in one of our busiest lines, 10 full skids of work (approximately 12 days of production) that they needed to start receiving back in their facility 2 days after we started to receive their product, we were eager for the challenge. Because they were able to give us advance notice, we were able to put our new Purchase Orders In-Advance (POIA) approach to the test.

The Solution

In 2022, we formally established a new team that would handle both customer account management and production planning. The goal was to give our planners the ability to better understand and solve our customers’ delivery needs and give our customers direct access to the people that create LMC’s production schedules. This partnership would not only improve our delivery performance for those customers but also change our reputation from anodizers to problem solvers.

After this team’s inception, our Purchase Orders In-Advance (POIA) concept was immediately introduced, or as Ralph Walsh, Senior Account Manager, calls it, “your LMC E-ZPass.” When our customers know they need to use LMC’s metal finishing services, they send us a PO with the necessary information: PO #, part number, and estimated quantity. With this information, we can get the order scheduled, work instructions reviewed, and potential issues corrected before the product arrives. We can also plan our resource needs, equipment maintenance, and chemical checks more efficiently and conveniently which shortens turn times, lowers costs, and therefore affords more competitive pricing.

The Outcome

Precision Form Inc. quickly and successfully aligned themselves with our mission, and leveraged our POIA approach to expedite their 10-skid order. We were able to schedule their orders based on their estimated arrival date and encouraged them to send quantities as they were completed in their process instead of waiting until everything was ready. When the first parts arrived the day that they expected to, we were able to anodize and sort them and start shipping them back the next day. This started a chain reaction so that the LMC teams were able to get into a routine over the next 4 days, with daily shipments leaving our facility as the next orders arrived. With the typical “Batch and Ship” standard broken, and the orders already scheduled at LMC, our customer was able to reap the benefits and turn past due orders into on-time and early orders.

Since then, our partnership with Precision Form Inc. has transformed their lead times, cutting what was a 10-15 day turn, to an average of less than 5 days.