Some Big Changes Are Happening At LMC!

We are fundamentally changing our shop floor operations to better support our customers and help us accomplish our daily production goals all while keeping quality & compliance a top priority. How will we do it? With a newfound focus on teamwork and collaboration.

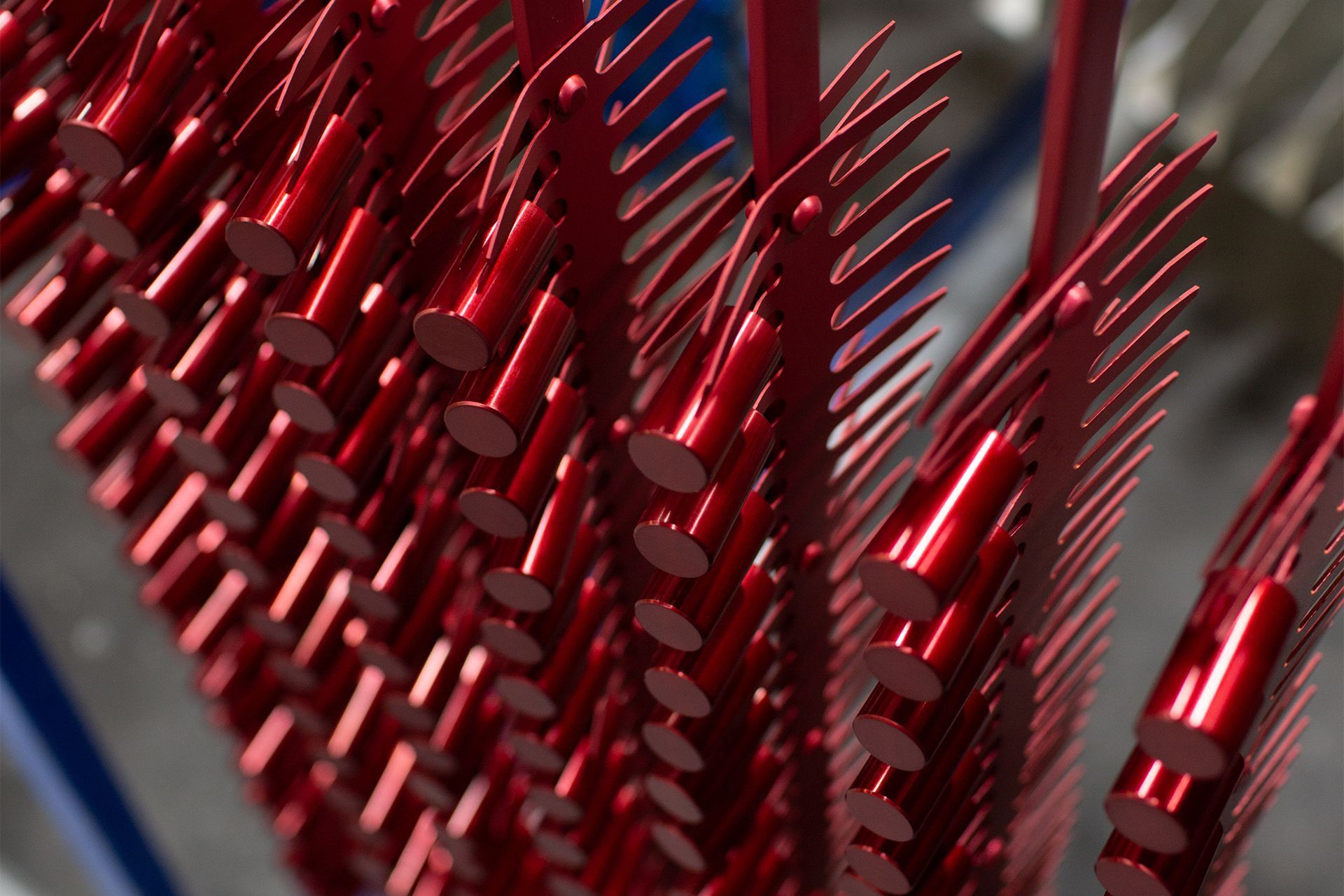

While the ultimate goal of our entire production unit is to safely produce a quality, metal finished product, at rate, at cost, and compliantly, each of our three new departments is made up of functions and roles that share a more specific objective. Below are a few ways in which we will accomplish the goal of production:

- Job Prep Department – We will control our raw material, chemistry, equipment, supplies, tooling, and people to ensure we effectively receive, inspect, clean, blast, mask, and rack.

- Coating Department – We will ensure we effectively coat our product to customer specifications by controlling our chemistry, equipment, tooling, and people.

- Order Prep Department – We will ensure we effectively unrack, sort, inspect, pack, ship, skid, and deliver our product on time to our customers, as well as only delivering what the customer is expecting through control of our tooling, equipment, and people.

Each group will be led by one or more captains to keep the team focused on achievement and continuous improvement. Complete implementation of this new approach will be finalized by the end of Q4 2021. We’re excited for yet another major milestone in reaching our long-term vision for LMC! Contact us today for quality anodizing services, phosphate coatings, and other metal finishing services.